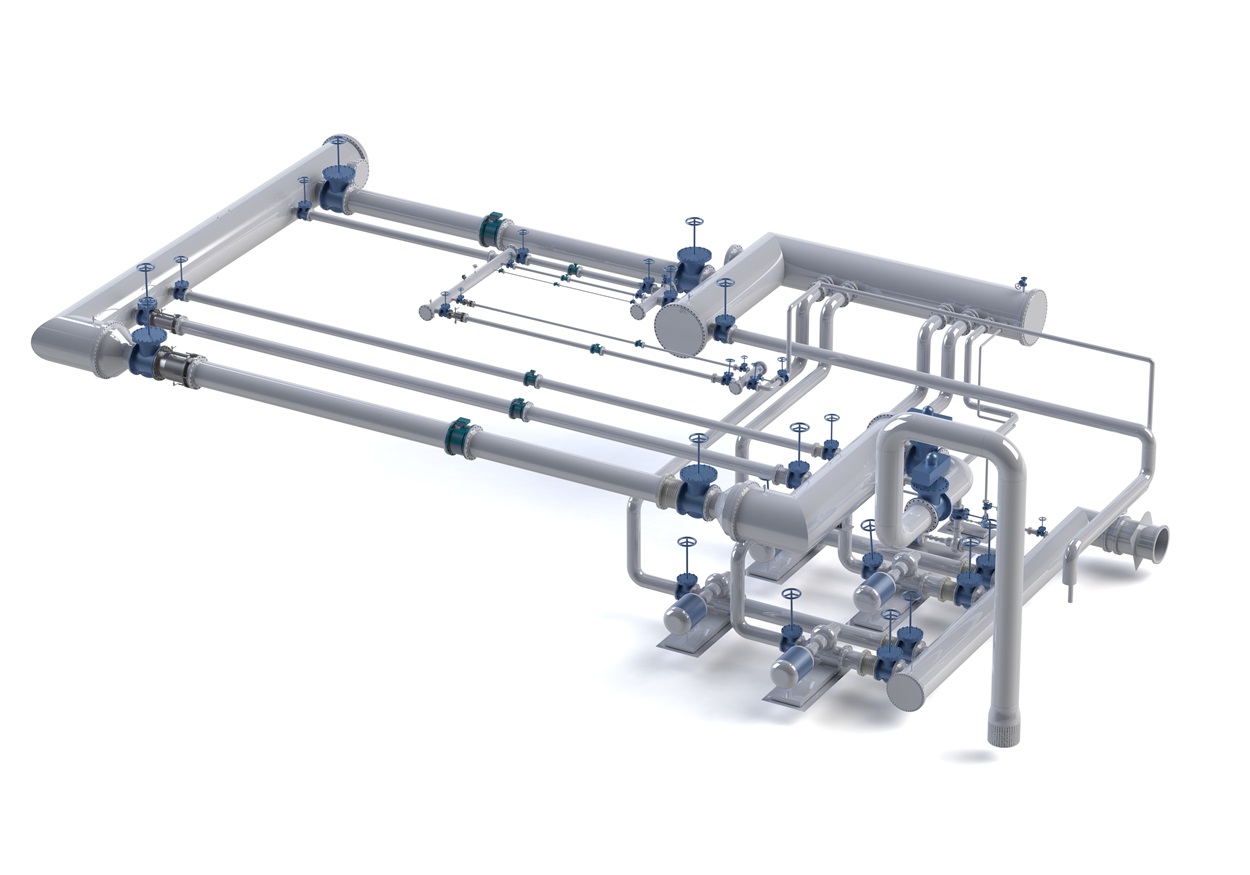

Blowdown refers to the process of releasing pressure from a pipeline, vessel, or system to safely lower the internal pressure, remove accumulated impurities, or maintain operational safety. It is commonly used in industries such as oil and gas, power generation, chemical processing, and water treatment. During blowdown, fluids like gas, steam, or water are discharged in a controlled manner to prevent damage to the system and ensure that it operates within safe pressure limits.

One critical component in a blowdown system is the restriction orifice. The restriction orifice is a specially designed flow control device that helps manage and regulate the flow of fluid during the blowdown process. It serves several key functions:

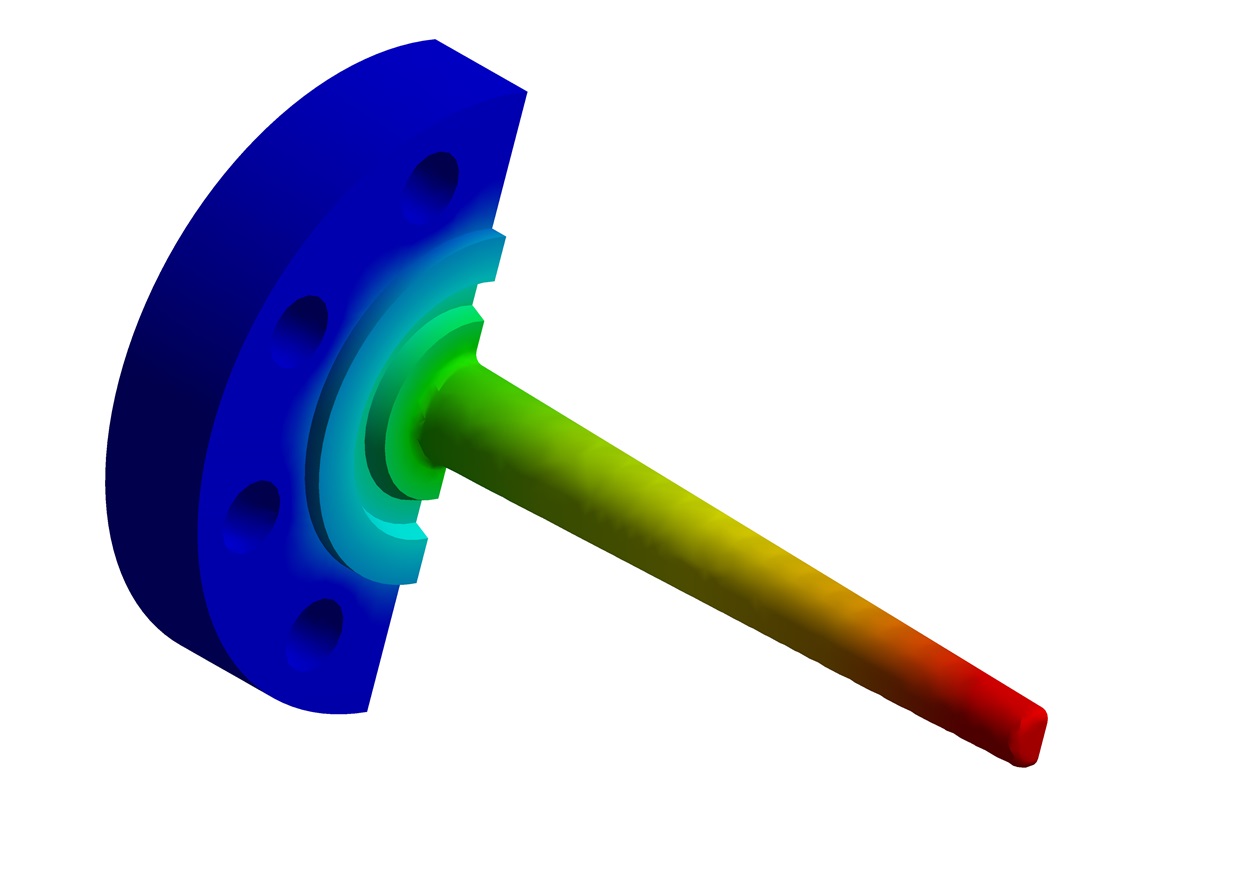

1. Pressure Control: The restriction orifice ensures that the pressure within the system is released gradually and safely, preventing rapid depressurization, which could lead to system instability or damage.

2. Flow Rate Limiting: By constraining the flow of the fluid, the orifice maintains the desired flow rate during blowdown, preventing excessive discharge that could damage downstream components or cause erosion.

3. Noise and Vibration Reduction: A properly designed restriction orifice helps minimize the noise and vibration that can occur during blowdown, which are often caused by turbulent fluid flow. This is especially important in systems operating under high pressure.

4. Cavitation and Choking Prevention: The restriction orifice helps to manage cavitation (the formation of vapor bubbles) and choking (where the flow is excessively restricted) during blowdown, both of which could cause damage to the equipment and affect system performance.

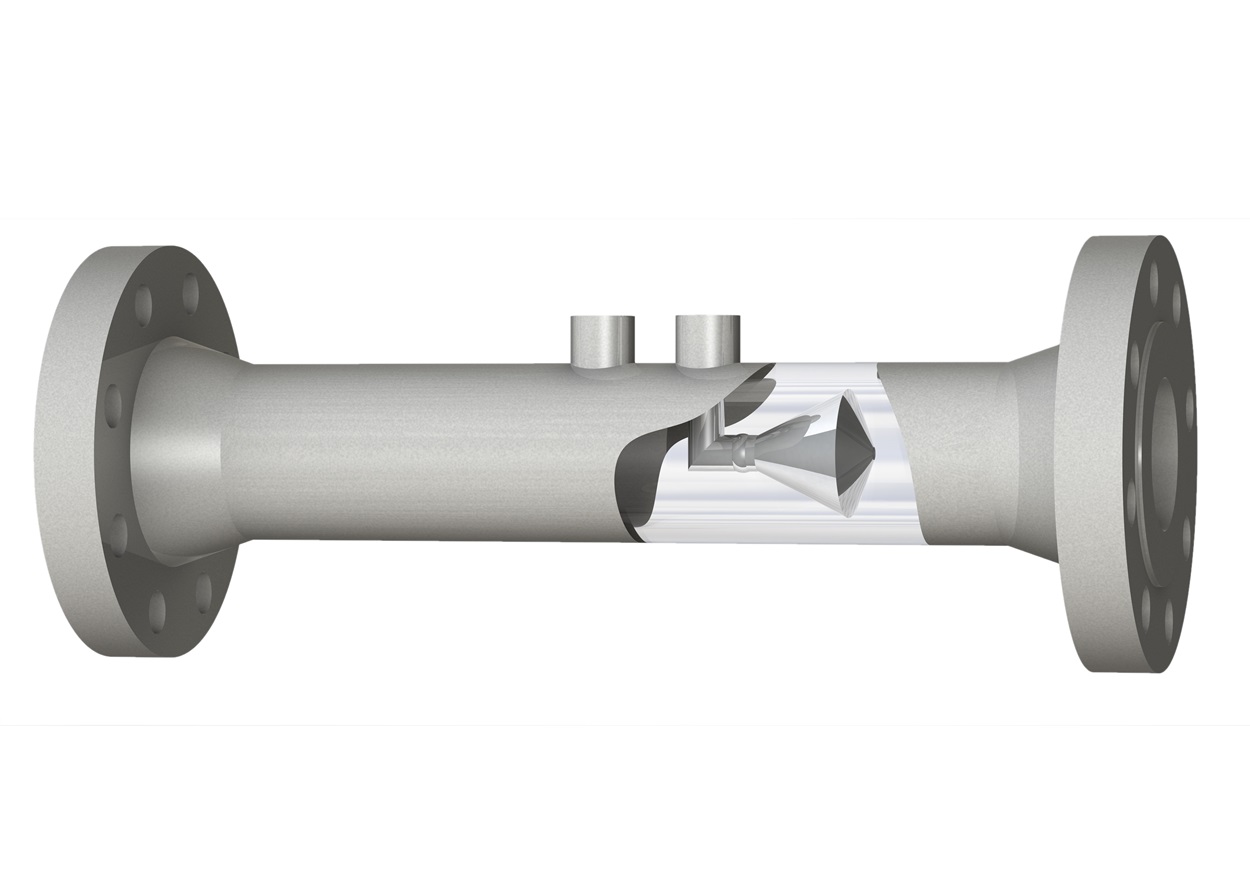

Cone flow meters are a reliable, efficient, and accurate solution for flow measurement, particularly in applications with space constraints and demanding operational conditions. Their design and performance advantages make them a preferred choice for industries seeking long-term, cost-effective solutions.

Advantages of Cone Flow Meter

1. High Accuracy and Repeatability

Cone flow meters provide precise and consistent flow measurement, even in challenging flow conditions. Their accuracy is typically within ±0.5%, with excellent repeatability of ±0.1%.

2. Low Straight Pipe Length Requirements

Unlike other DP flow meters, cone flow meters require minimal upstream and downstream straight pipe lengths, making them ideal for installations in compact spaces or complex piping systems.

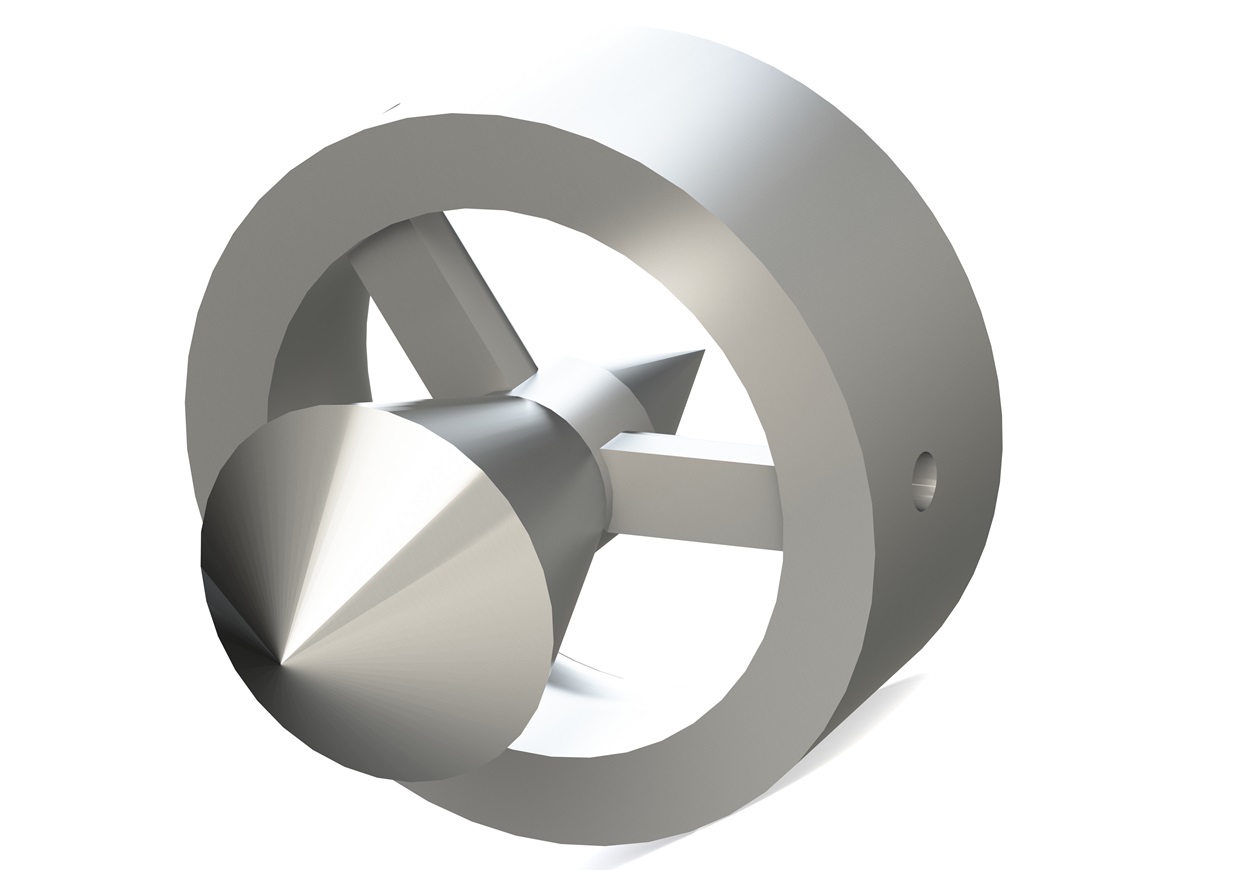

3. 6. Improved Flow Profile

The cone design conditions the flow, reducing turbulence and providing a stable flow profile for more accurate measurements, even in cases of distorted or irregular flow.

Ph: +91 8156 876 876

Email: krtyata.info@krtyata.com

©2025 Krtyata Private Limited. All rights reserved. Privacy Policy