Sonic Nozzles

Critical Flow Venturi or Sonic Nozzle are using in many industries and research applications.

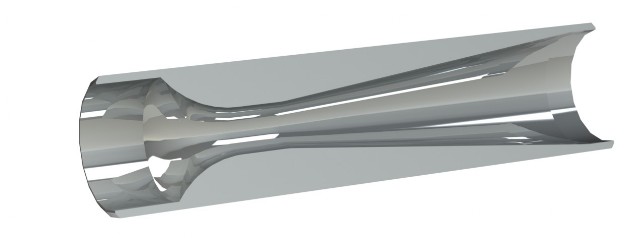

Because of its high repeatability and reproducibility, it is using in master calibration of air and gas flow measurement devices.A critical flow venturi is a convergent-divergent restriction inserted into a system and is used to

determine the mass flow rate of gas flowing through a system.In this the gas flow accelerates to the critical velocity at the throat.

And this critical velocity condition is considered as choked or sonic.

When the flow is at critical state, increasing the differential pressure will not affect the fluid flow rate.

Critical Flow

Critical flow is the maximum flow rate for a particular venturi that can exist for the given upstream conditions.

When critical flow exists, the throat velocity is equal to the local value of the speed of sound (acoustic velocity).

Advantages of Critical Flow Venturi:

By the Critical Flow Venturi, the mass flow can be determined solely by the state of fluid stream at the inlet of the venturi,

there is no need for the differential pressure measurement to calculate the flow rate as in the subsonic DP flow elements.

So in this, by eliminating the downstream pressure tap, flow rate is not affecting by downstream flow disturbances.

And the mass flow is constant with varying downstream pressure.

The nearly linear relationship between the mass flow and the inlet stagnation pressure, at constant temperature,

is an advantage over the square-root relationship between the low and the differential pressure measurement in as subsonic DP elements.

The total pressure loss over its flow range from frictional effect is low.

Critical flow meters are relatively unaffected by the disturbances in the inlet fluid stream, other than swirl.

The discharge coefficient is only a function of the throat Reynolds number.

In CFV, the Mach number at the inlet of venturi is nominally equal to 1.

So, the uncertainty in the predicted discharge co-efficient is comparatively lesser than the subsonic DP elements.